Caliper Pig

Principle of operation

The Caliper Pig measures diameter reductions in pipelines such as dents and ovalities.

Even diameter variations like girth-welds, wall thickness changings, T-pieces, valves and other installations are detected.

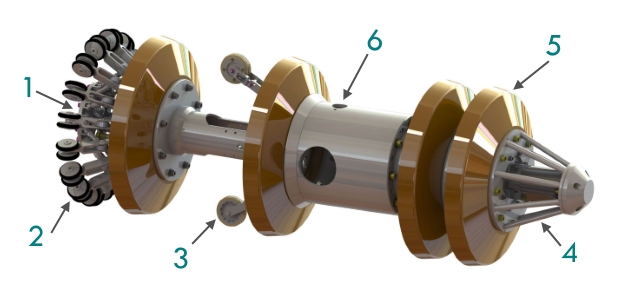

Components

- Transmission disc

- Sensing fingers

- Odometer wheel

- Locator unit

- Drive cup

- Digital data recorder

Function

The Caliper Pig continuously measures the inside diameter of the pipeline through an array of sensing fingers ("spiders") that are spring loaded to hold them in contact with the pipe wall. A large number of sensing-fingers provide optimum coverage of the inside circumference. Wheels at the end of each sensing-finger are in direct contact with the pipe wall. The extremely flexible polyurethane cups enable the Caliper Pig to be transported through the pipeline by the medium. The Caliper Pig is able to pass reductions of at least 25%.

The spider is separate from the cup to eliminate effects from cup wear. As the Caliper Pig moves through the pipeline, all radial sensor movements are detected and recorded. ID-reductions of 0.4% will be detected.

Odometer wheels generate the distance data which in addition to the measuring data from the spider is continuously collected and stored together with the correlative diameter values.

To locate the Caliper Pig in the launcher, receiver or during survey, a locator unit is used. The locator unit transmits electromagnetic signals which will be detected by an external inspection tool locator. A pushing flange is used to push the Caliper Pig into the launcher and to protect the spider against mechanical damage.

The data-recorder contains all power, processing and recording circuits in a sealed module within the central body of the Caliper Pig.

Calibration

Prior to the survey the Caliper Pig is calibrated by using a calibration ring and simulating dents and ovalities with small blocks of specified thickness. These calibration outcome is used to draw the calibration curve, which forms the basis to determine the diameter reduction which corresponds to the deflection on the chart.

The calibration will be done in 2.5 or 5 mm steps. Each survey chart shows a dent-calibration and a ovality-calibration at its beginning.

Data analysis and interpretation

Analysis

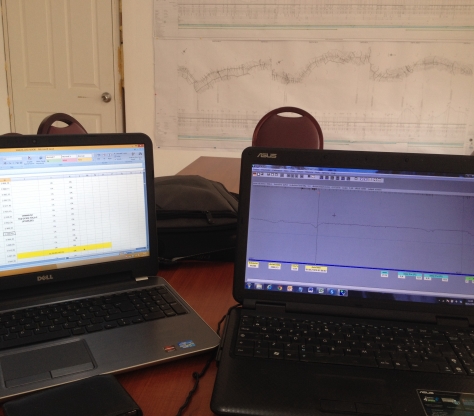

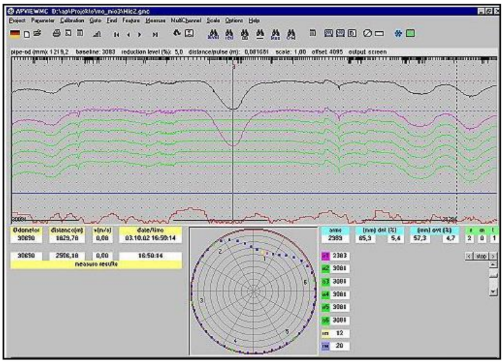

During the survey the Caliper Pig data are gathered in the solid state memory inside the recorder. After the run a laptop computer is connected to the Caliper Pig to download the data. The visualization of the survey chart is done on the laptop itself. The interpretation of the complete survey data will be done directly on screen. All interesting details are marked in the chart and a printout is added to the report.

Interpretation

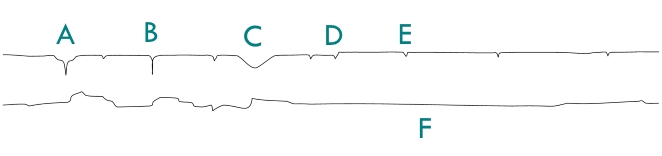

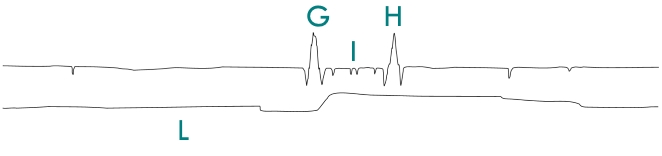

Before interpretation begins a minimum acceptable diameter reduction is agreed with the customer. The interpreter scans the chart for deflections which exceed the agreed value and compiles a features list. All indications exceeding the agreed value and also pipeline features like valves, T-pieces, wall thickness changes, girth-welds, bends and other installations are listed.

The following examples show typical pipeline features:

Final report

The Data Analysis Department consists of experienced people who work close together with the customer and service technicians.

The Final Report generally contains the data listed in the table.

The General Informations provides details like names of the pipeline owner, the surveyd pipeline and the names of representatives and technicians.

Technical Data shows all important data concerning the pipeline the Caliper Pig and the survey run.

Details of how the job was carried out, principles of dates of the survey and progress of the job are given under Survey Procedures.

The Results are summarized in the features list. It contains several columns with all the important notes of the run.

Supplementary to the features list the calibration curves and the entire Printout of the chart is provided.

- General informations

- Technical data

- Survey procedures

- Results

- Features list

- Calibration curves

- Printout of chart

Multi-Channel Caliper Pig

The Multi-Channel Caliper Pig - technology fully owned and developed by Trecoil S.r.l. - provides a complete geometrical pipeline analysis thanks to its added module of features detection, which lalows the tool to reveal the clock position of the defect, as well as its linear progressive position.

Geometrical defects of a pipeline are of various nature. Knowing also their clock-position on the circumference of the pipeline greatly helps to determine their possible cause of generation, together with guiding excavating and repairing activities.