Highest quality pipeline services - Proud Italian Excellence

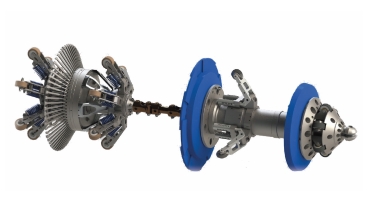

Caliper Pig

Inspection Tools

Intelligent

Inspection Tools

Engineering

services

Nitrogen

purging line

Pipe

drying

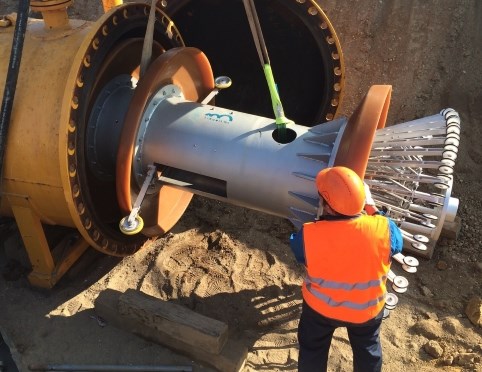

Intelligent Pig

Intelligent pig inspections return a complete report of the conditions of the pipeline. This include corrosion and degradation status brought by chemical agents. Intelligent inspections are able to detect any different in the thickness of the wall and the linear position of the feature.

Cleaning

The operation of cleaning is carried out with bi-directional pigs and thier passage through the line. It allows to remove residues which may be present inside the line and to prepare the best set for successive geometrical-dimennsional inspections or maintenances such as drying and nitrogen purging.

Nitrogen Purging Line

Inertization through nitrogen ensures safety of pipeline and makes the working environment safe. It is required to maintain a pipeline in a non-stressful condition. It is also required when a maintenance intervention is needed so it can be freely performed without compromise for safety.

MISSION

To guarantee to as many people as possible an efficient and safe system for the distribution of energy.

VISION

We aim at the optimal relationship with people, offering complete and ever-evolving services and choosing the solution which implies the broadest added value.

Pipeline Inspections

Trecoil S.r.l. carries out geometric inspections and testing pipeline at the main customers in the oil and gas market and quality, safety, environment and energy training activities.

Our team is a group of experienced and well trained professionals who know how to get things working. Although we are a young company in inspection area, most of us have long time experience in working with intelligent pipeline tools.

Inspection measurements

The Caliper Pig measures diameter reductions in pipelines (from 6" to 56") such as dents and ovalities.

Even diameter variations like girth-welds, wall thickness changings, T-pieces, valves, bends and other installations are detected.

Some projects

Here some projects we worked on. Click the following button to know more about them.